Existing Roller Shutter Box Insulation – Effezeta Brand – Insulating Panels in Various Sizes

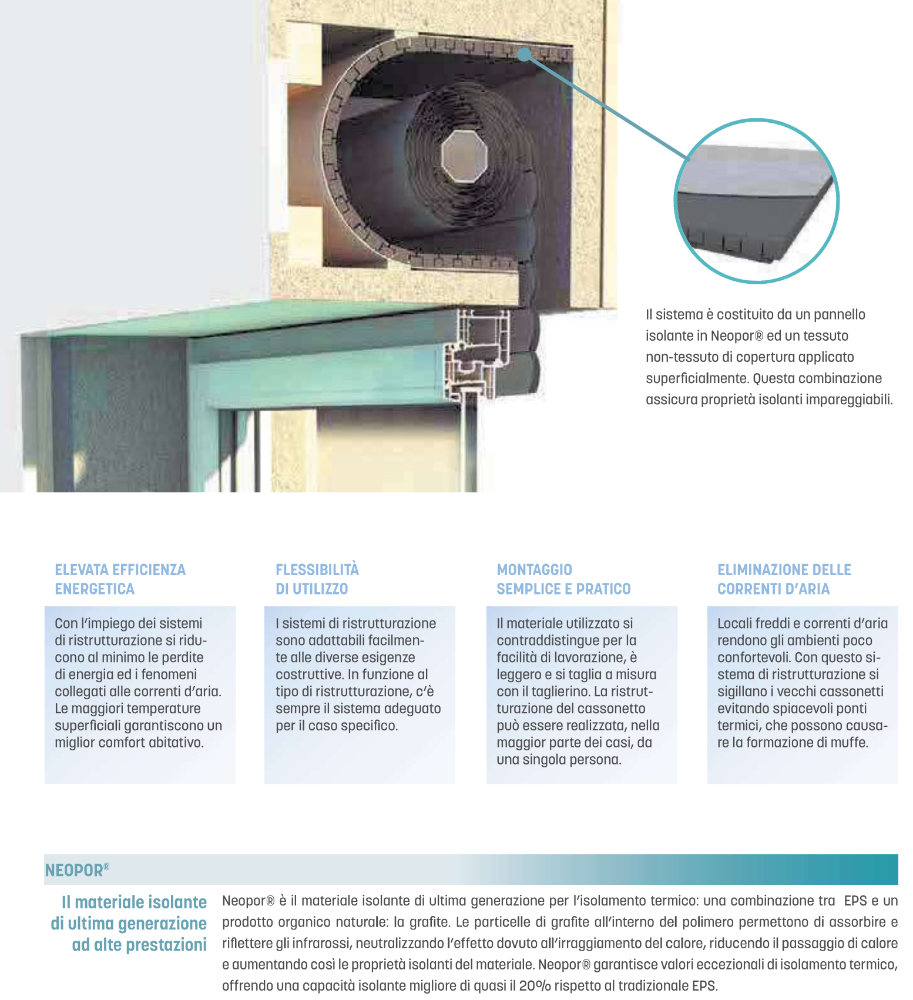

Professional system for

insulating existing roller shutter boxes , designed to reduce heat loss, drafts, and air currents. Ideal for renovations without demolition, it significantly improves living comfort and the building's energy efficiency.

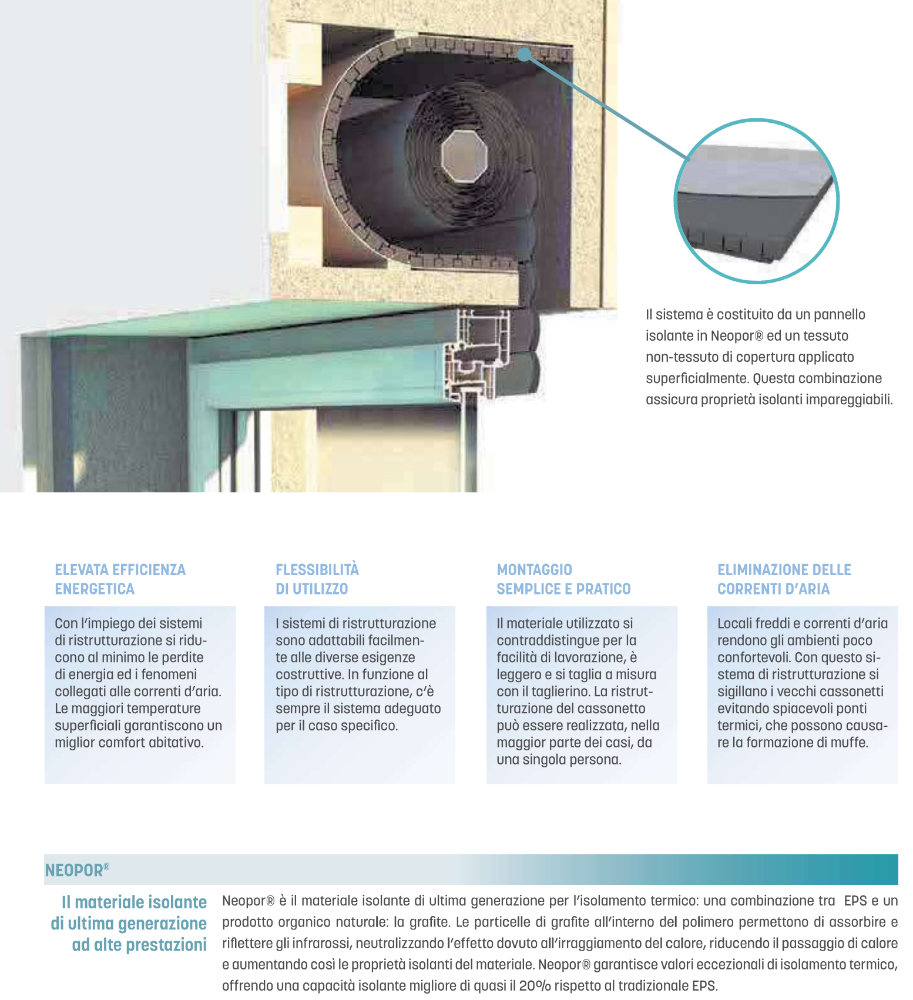

The Effezeta system for insulating existing boxes is made with

insulating panels in Neopor®, a latest-generation insulating material with high thermal performance.

Thanks to its

flexible structure and T-cuts, the panel easily adapts to the internal shape of the box, ensuring simple installation and optimal insulation even in irregular situations.

It can be ordered online either as a single panel or as a two-component system, which also includes the rigid base for the box floor, for an even more effective seal against thermal bridges and air infiltration.

Product with selectable variants based on:

- System type;

- Dimensions;

- Insulation thickness.

Insulation panel

- 1000 × 500 × 13 mm

- 1000 × 790 × 13 mm

- 1000 × 500 × 25 mm

- 1000 × 790 × 25 mm

Two-component system (panel + rigid base for platform)

- 1000 × 500 × 13 mm

- 1000 × 790 × 13 mm

- 1000 × 500 × 25 mm

- 1000 × 790 × 25 mm

Isolated flank

Advantages of the roller shutter box insulation system

- High energy efficiency with reduced heat loss;

- Elimination of drafts and currents;

- Better living comfort and warmer internal surfaces;

- Quick and easy installation, even by one person;

- Lightweight, flexible and easily shaped material;

- Ideal solution for renovating existing containers.

Product applications for insulating existing boxes

- Roller shutter boxes already installed;

- Energy requalification interventions;

- Elimination of thermal bridges in windows and doors;

- Improved thermal insulation and internal comfort.

Neopor® insulation material

Neopor® is a

high-performance insulation material derived from EPS with added graphite. The graphite particles reflect and absorb infrared radiation, improving thermal insulation by up to approximately 20% compared to traditional EPS at the same thickness.